Photos of Mold Oscillating Servo Cylinders

Mold Oscillating Servo Cylinders

The mold oscillating servo cylinder enables the mold in the slab continuous casting production line to perform arc motion along the radius of the continuous casting machine. This motion is governed by specific amplitude, frequency, and waveform deflection characteristics, facilitating the mold’s up-and-down oscillation. The controlled sequential vibration ensures lubrication and prevents adhesion between the casting steel and the mold wall.

The Uranus mold oscillating cylinder utilizes electro-hydraulic direct drive technology, enabling both sinusoidal and non-sinusoidal vibration functions. This system offers several advantages, including intelligent operation, high frequency, high precision, low maintenance, a long service life, and high reliability. Its design is simple and cost- effective, with easy installation and low maintenance. The system enhances casting speed, increases the output of the casting machine, and reduces energy consumption as well as operating costs while improving both production efficiency and product quality.

For over 20 years, we have produced hundreds of mold oscillating cylinders in more than 20 different types. Below are several examples of our mold oscillating cylinders:

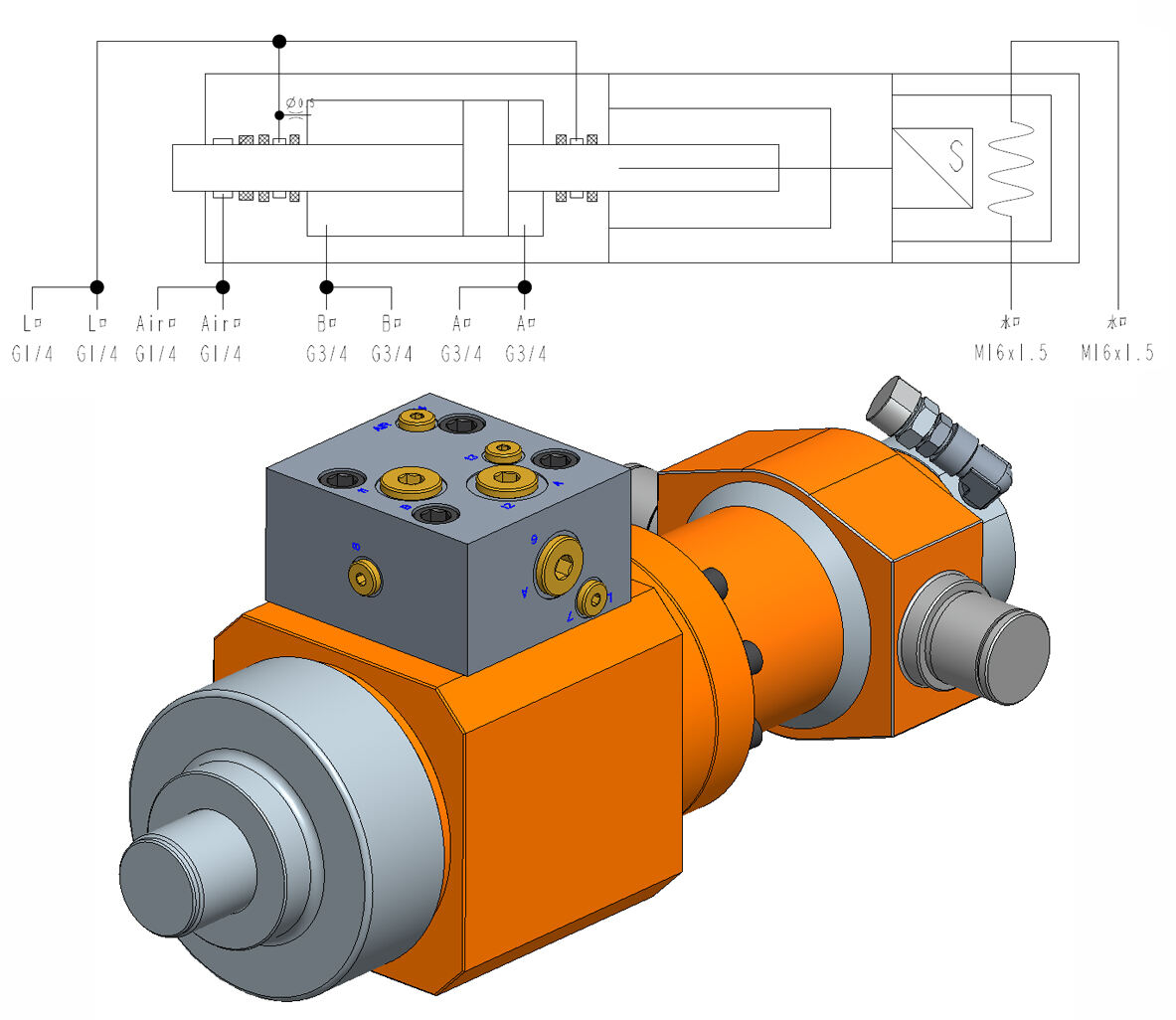

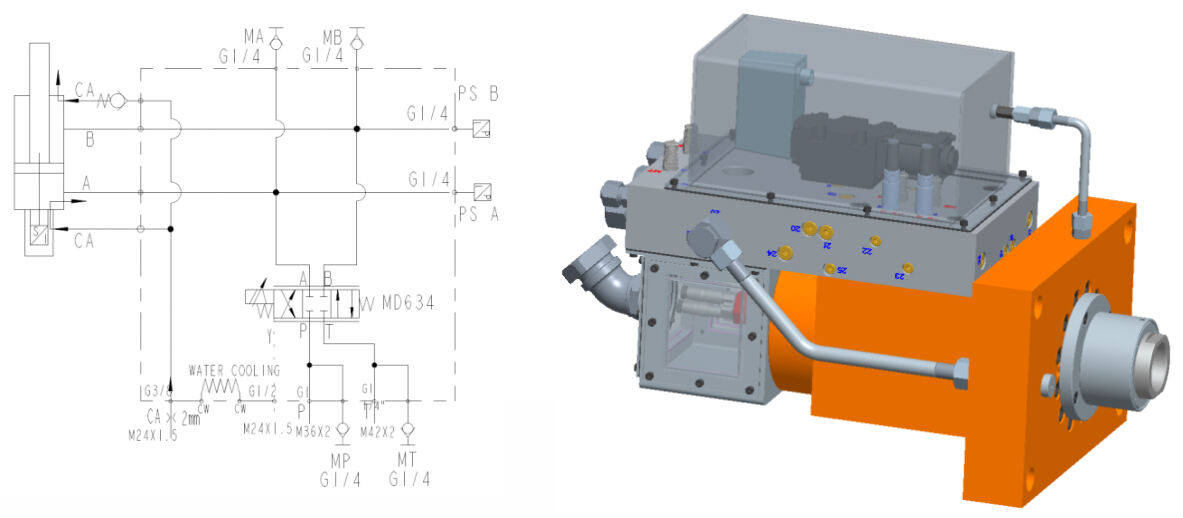

1. Technical parameters:

Cylinder diameter: 125; rod diameter: 90; stroke: 25;

Rated pressure: 21 MPa; test pressure: 31.5 MPa

A closed-loop control system of built-in displacement sensor and servo valve allow the vibration cylinder to achieve both sinusoidal and non-sinusoidal vibration.

A servo valve box is mounted on the servo valve block, and high-pressure gas is introduced into the valve box and the piston rod dust cover to prevent dust and provide cooling. This setup effectively extends the service life of the mold oscillating cylinder.

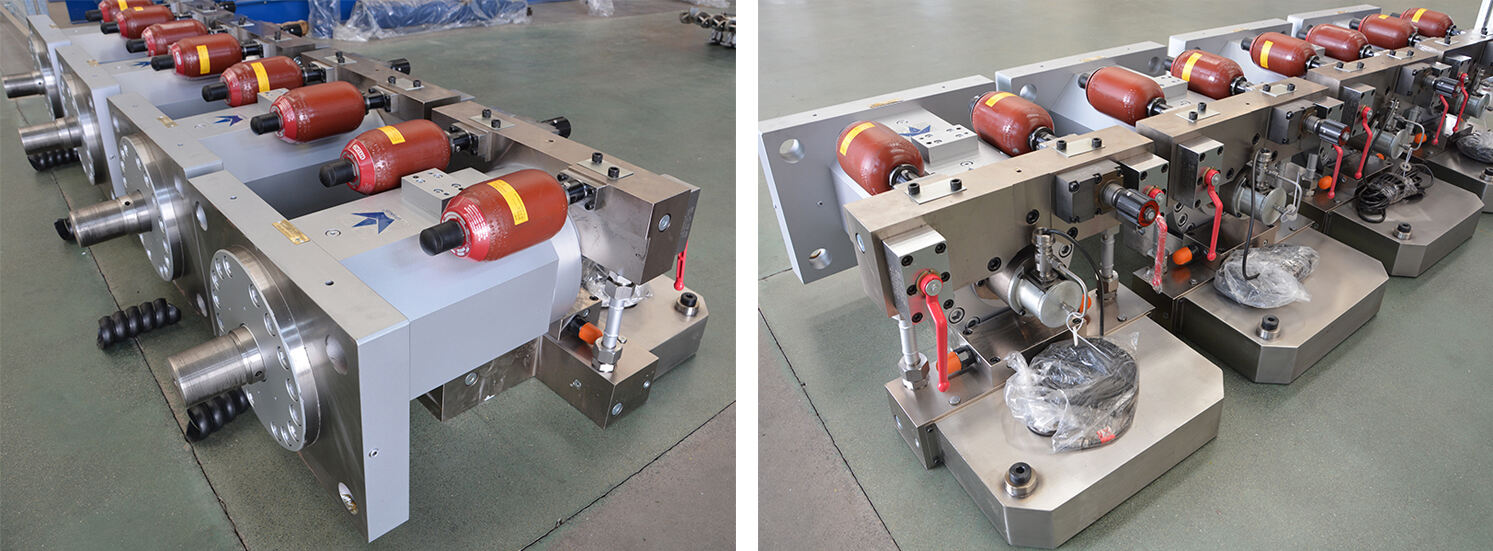

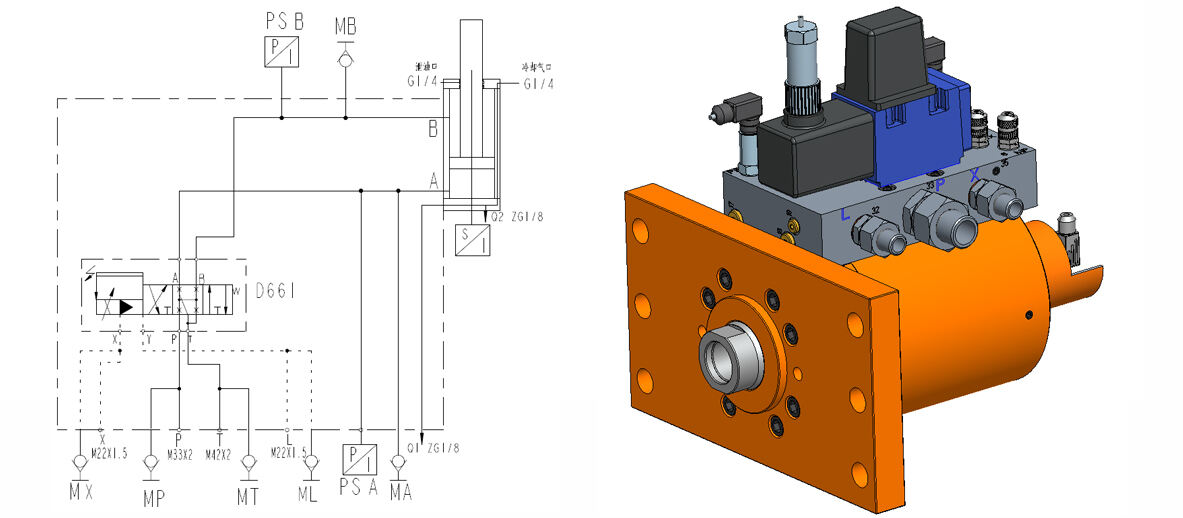

2. Technical parameters:

Cylinder diameter: 200; rod diameter: 90; stroke: 25;

Rated pressure: 21MPa; test pressure: 31.5MPa

The vibration cylinder has a built-in displacement sensor and an accumulator with various hydraulic valves installed on the servo valve block. The closed-loop control achieves sinusoidal or non-sinusoidal vibration of the hydraulic cylinder.

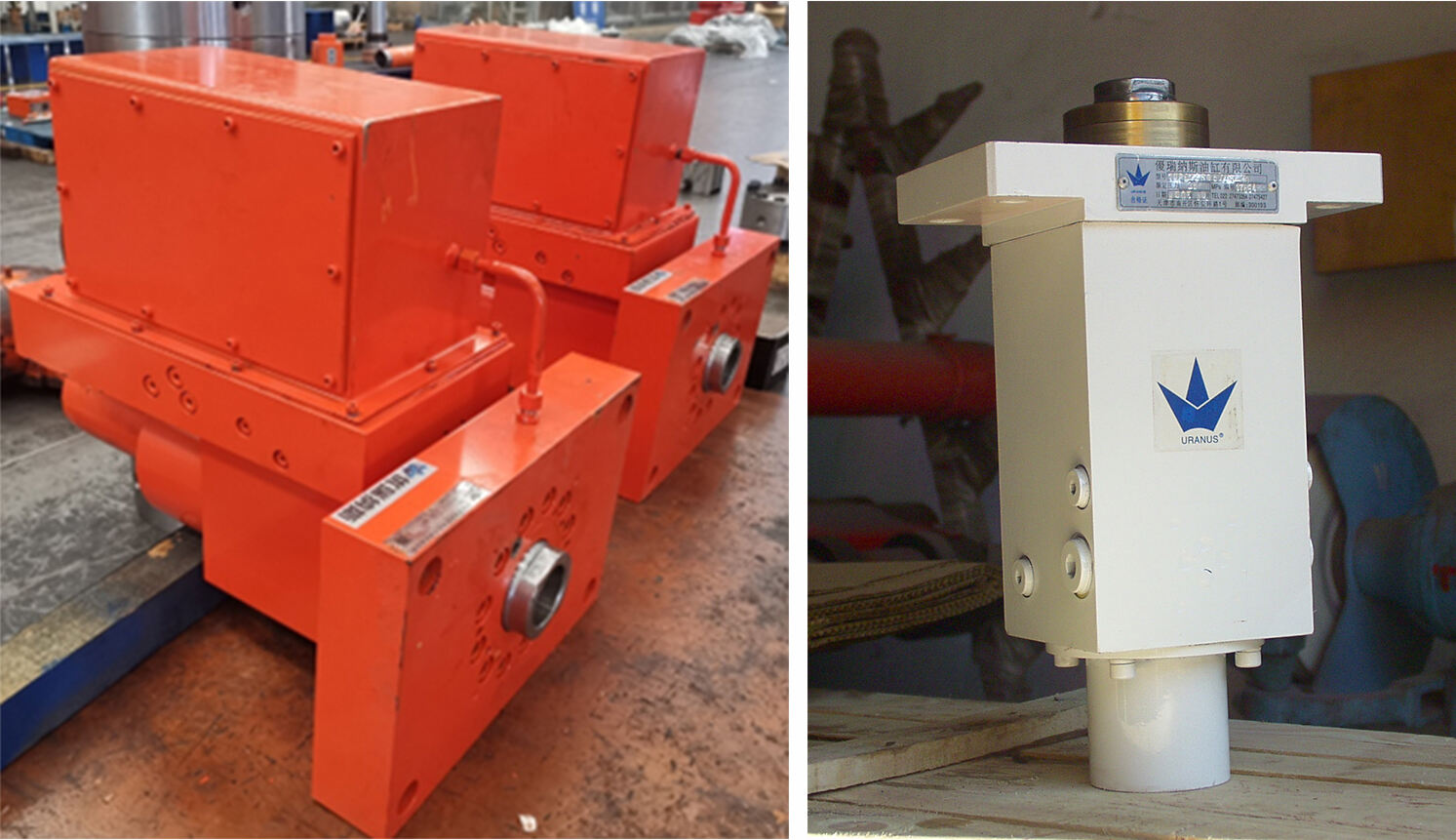

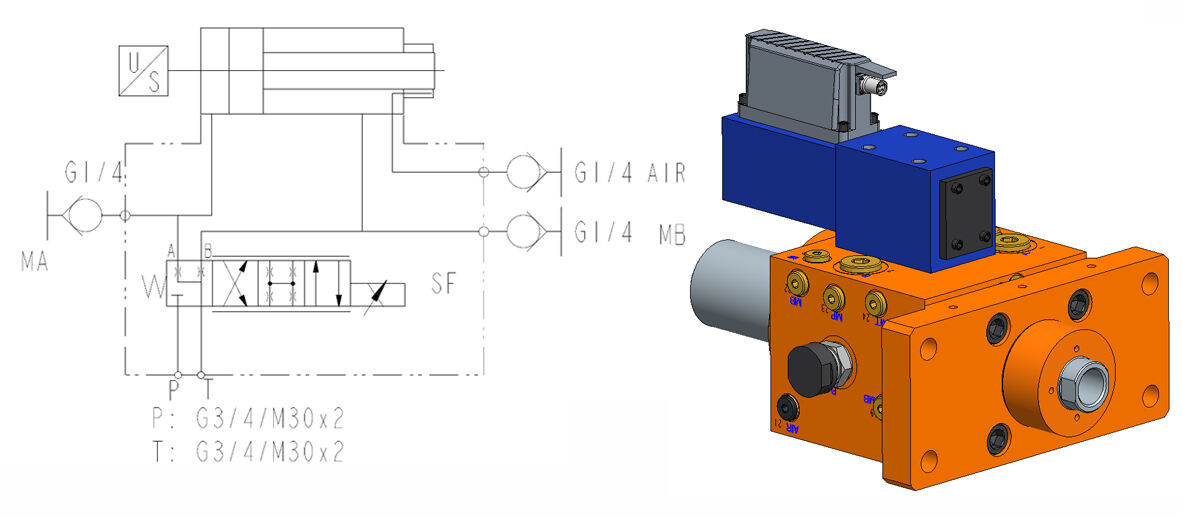

3. Technical parameters:

Cylinder diameter: 80; rod diameter: 45; stroke: 25;

Rated pressure: 25MPa; test pressure: 32MPa

The vibration cylinder is equipped with a built-in displacement sensor, with a servo valve installed on the servo valve block. This closed-loop control achieves sinusoidal or non-sinusoidal vibration of the hydraulic cylinder.

4. Technical parameters:

Cylinder diameter: 100; rod diameter: 70; stroke: 30;

Rated pressure: 21 MPa; test pressure: 25 MPa

The vibration cylinder is equipped with a built-in displacement sensor, with a servo valve installed on the servo valve block. This closed-loop control achieves sinusoidal or non-sinusoidal vibration of the hydraulic cylinder

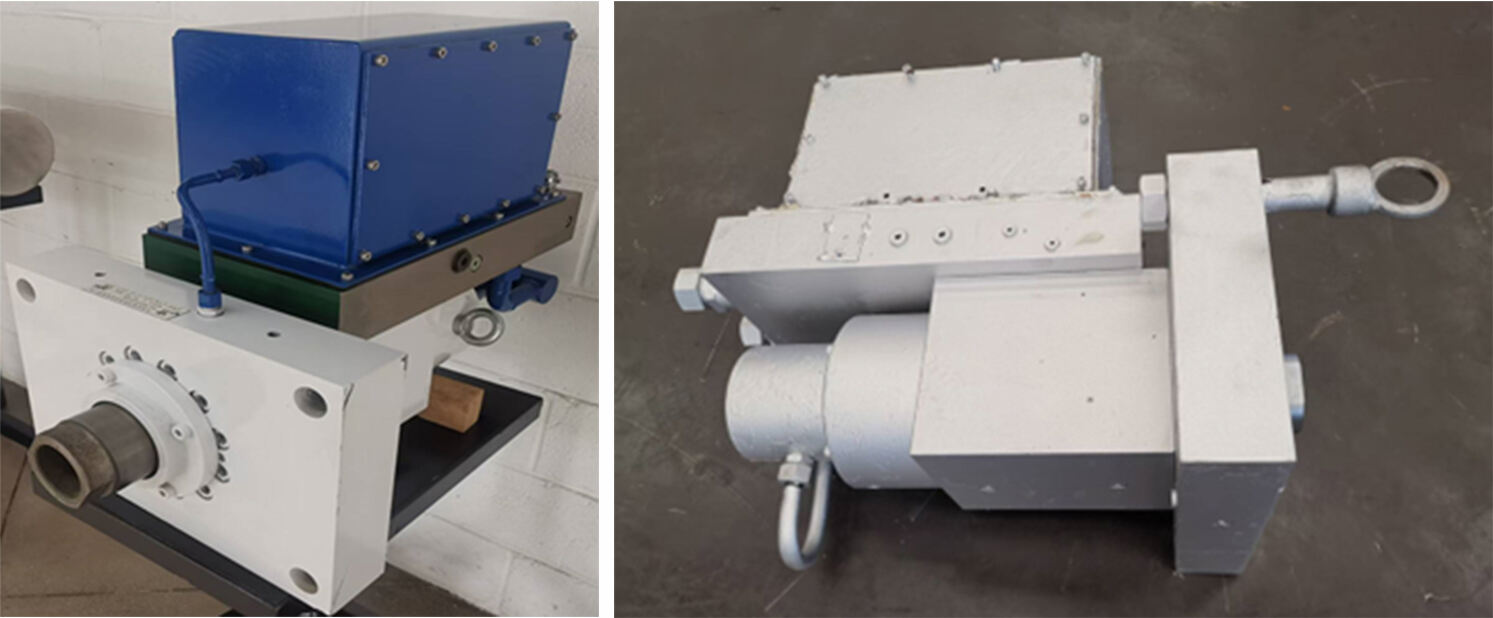

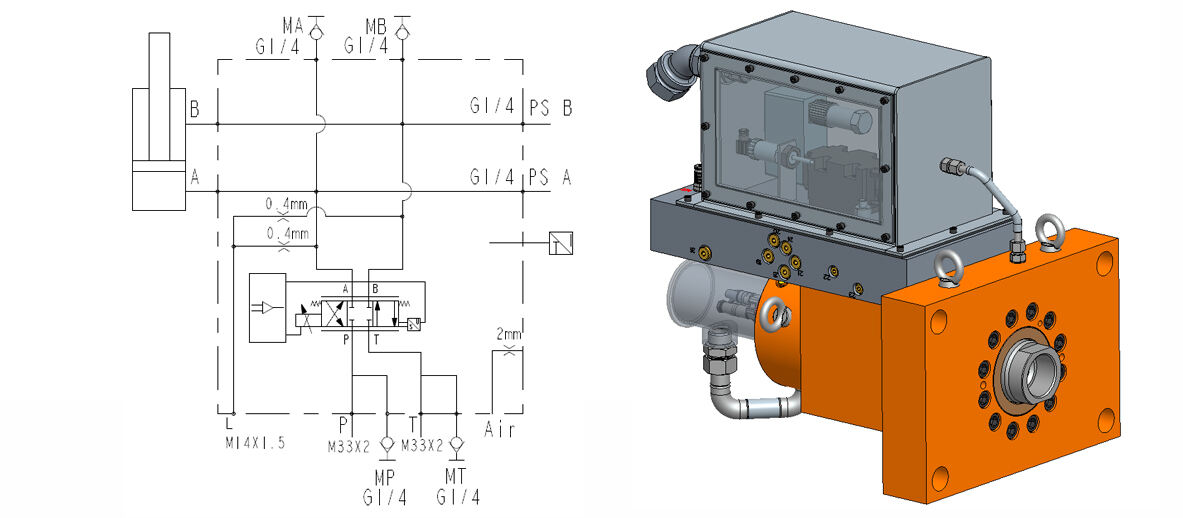

5. Technical parameters:

cylinder diameter: 125; rod diameter: 90; stroke: 25;

Rated pressure: 16 MPa; test pressure: 30 MPa

The vibration cylinder is equipped with a built-in displacement sensor and a servo valve. This closed-loop control achieves sinusoidal or non-sinusoidal vibration of the hydraulic cylinder.

A servo valve box is placed on the servo valve block, high-pressure gas introduced into the valve box as well as the piston rod dust cover to prevent dust ingress and provide cooling. This setup effectively extends the service life of the mold oscillating cylinder.

6. Technical parameters:

Cylinder diameter: 100; rod diameter: 70/70; stroke: 33

Rated pressure: 10MPa; test pressure: 15MPa

A double-rod constant-speed hydraulic cylinder with a built-in displacement sensor includes a cooling water pipe and a cooling sensor electronic compartment, ensuring that the sensor remains unaffected by high environmental temperatures.