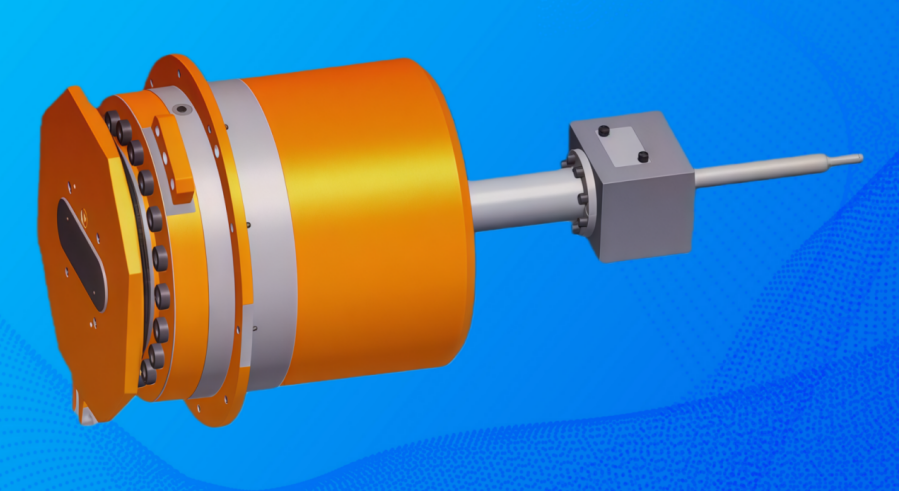

The AGC servo hydraulic cylinders utilize a design by URANUS, incorporating servo hydraulic cylinder seals.

The cylinder barrel is machined from 42CrMO forged steel, quenched, and tempered.

The inner bore surface is hard chrome plated with a coating thickness of 0.08-0.10 mm and a hardness of Hv800-900.

The piston rod is made of 42CrM0 forged steel, quenched, and tempered. The surface is hard chrome plated with a coating thickness of greater than or equal to 0.08-0.10 mm, and a hardness of Hv800-900.

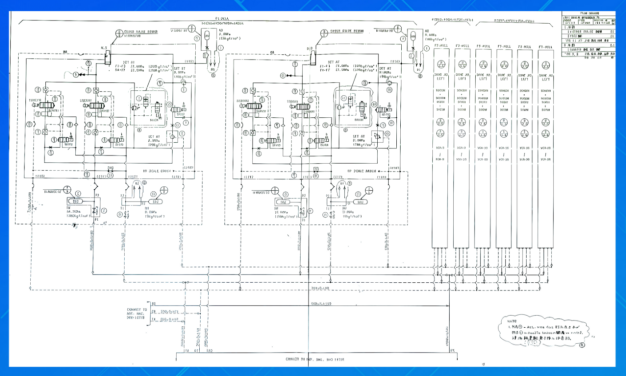

Factory testing is performed using a testing platform specialized for AGC servo hydraulic cylinders.

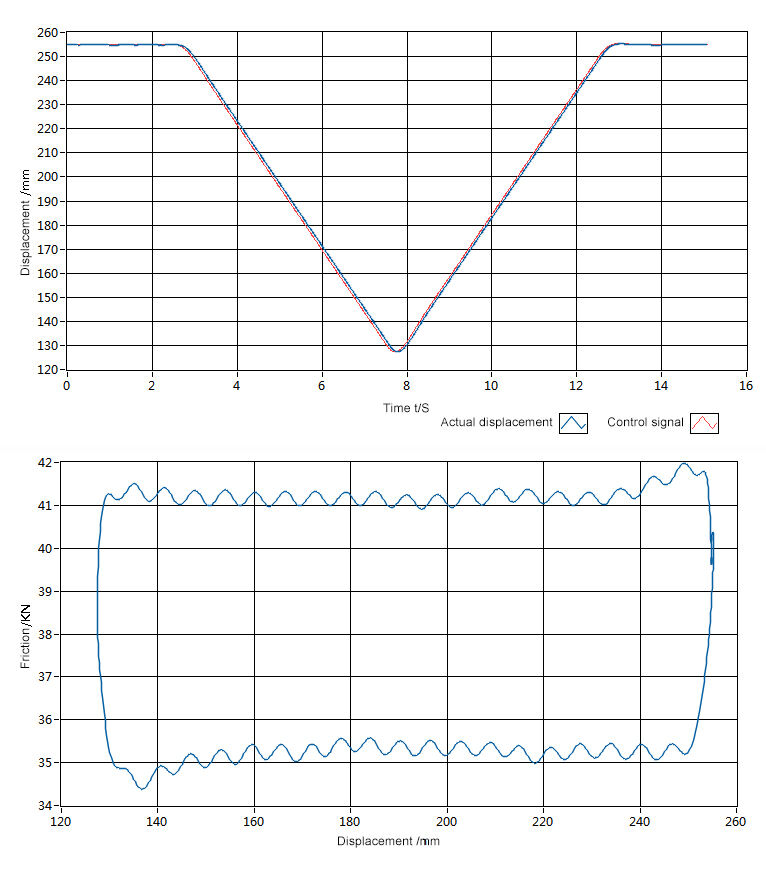

Friction performance test; provides dynamic and static friction curves.

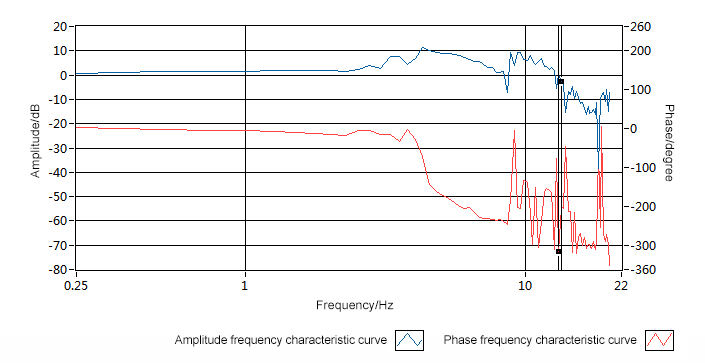

Dynamic performance test; provides step response diagrams and closed-loop logarithmic frequency diagrams.

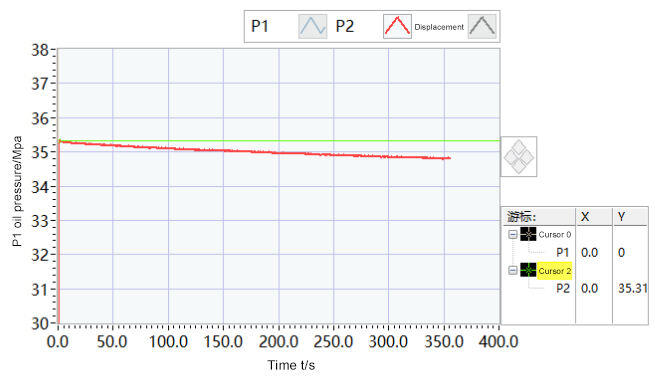

Internal leakage test; measures pressure drop under rated pressure conditions (≤ 0.5 MPa) and provides a pressure holding test diagram.

Testing oil cleanliness; ≥ NAS5 or above

Minimum starting pressure (≤ 0.05 Mpa)

Test pressure; 1.5 times of the rated pressure

Optional displacement sensor types include:

Optional Built-in/ external/ magnetic displacement sensors from MTS, BALLUFF or TR.

SONY magnetic scale sensor, LVDT displacement sensor,

Optional servo valve block, pressure sensor, exhaust and pressure measuring joint, etc. for rodless cavity end;

Optional spherical pad, accordion dust shield, and metal heat shield for piston rod end.

The servo cylinder has a warranty of 1 to 5 years vary by type.

Over 1000 AGC servo hydraulic cylinders have been supplied to customers globally.

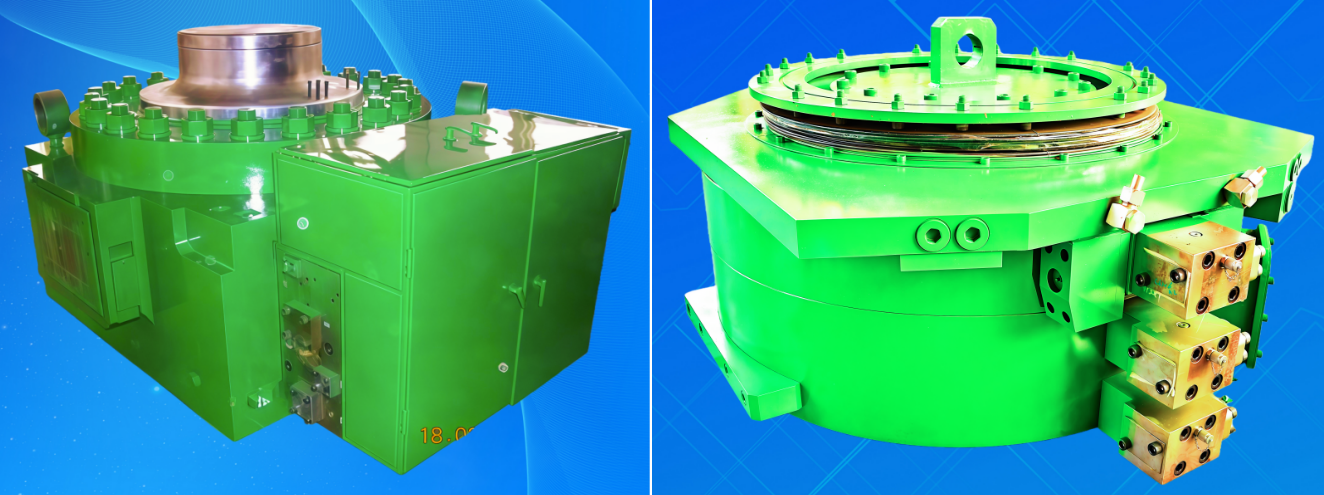

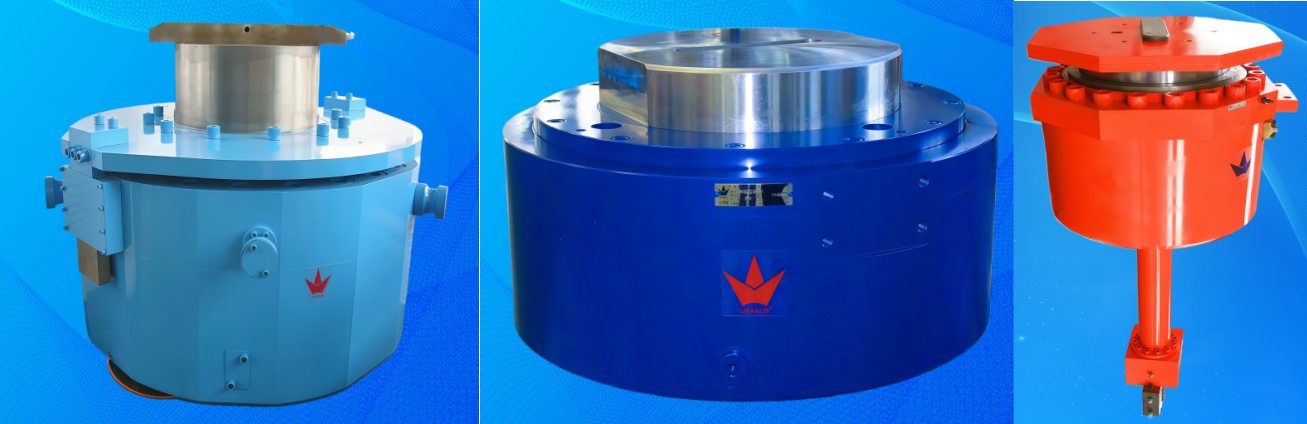

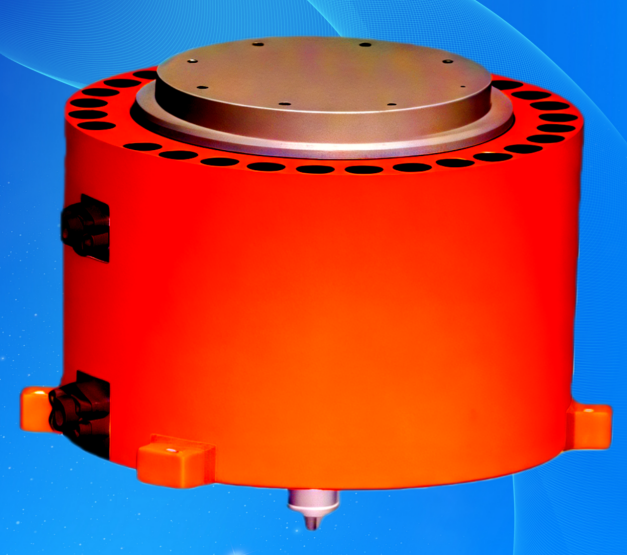

AGC Servo Hydraulic Cylinder

Automatic Gauge Control Cylinder

Uranus Hydraulic Machinery Co., Ltd.

A leading Chinese manufacturer of high-pressure, high-precision servo hydraulic cylinders, equipped with China’s largest 8000-ton AGC cylinder testing platform.

1. Product Overview

The AGC servo hydraulic cylinder is the core actuator of Automatic Gauge Control (AGC) systems in steel rolling mills.

It precisely adjusts the roll gap via closed-loop electro-hydraulic control, ensuring stable strip thickness at the mill exit.

Displacement, pressure, and gauge signals form a closed-loop feedback. The controller processes them through PID and drives the servo valve to achieve micron-level roll gap control, featuring high precision, fast response, and excellent stability.

Applications:

• Hot strip mills

• Cold rolling mills

• Temper / skin-pass mills

• Stainless steel, silicon steel, aluminum, copper strip lines

2. Technical Advantages

Strong Engineering & R&D Capability

• 40+ design engineers

• Over 30 years of AGC cylinder expertise

• Thousands of AGC cylinders delivered worldwide

Available for OEM based on drawings or custom design.

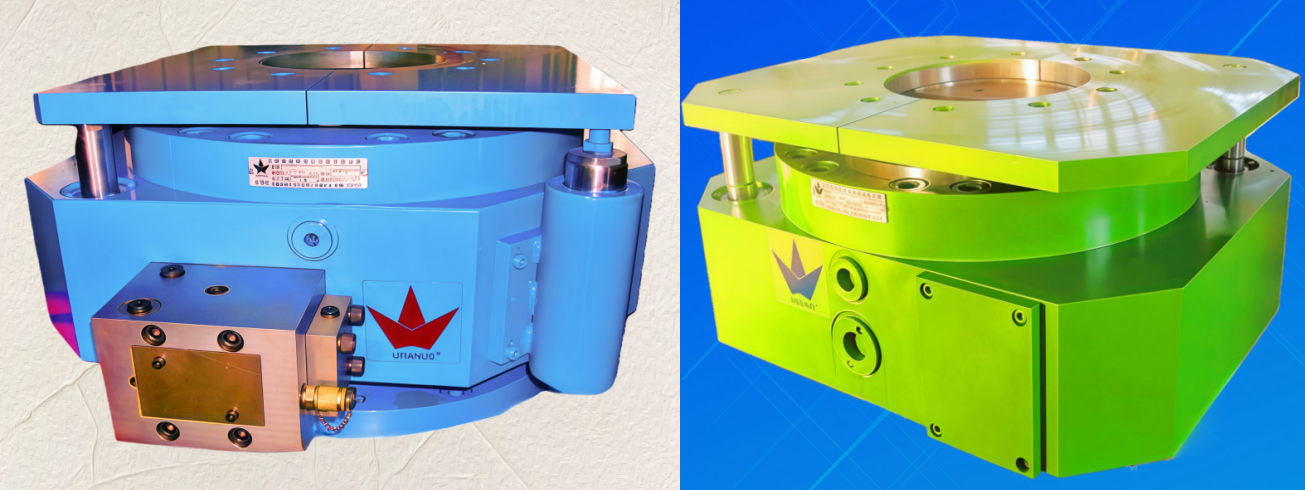

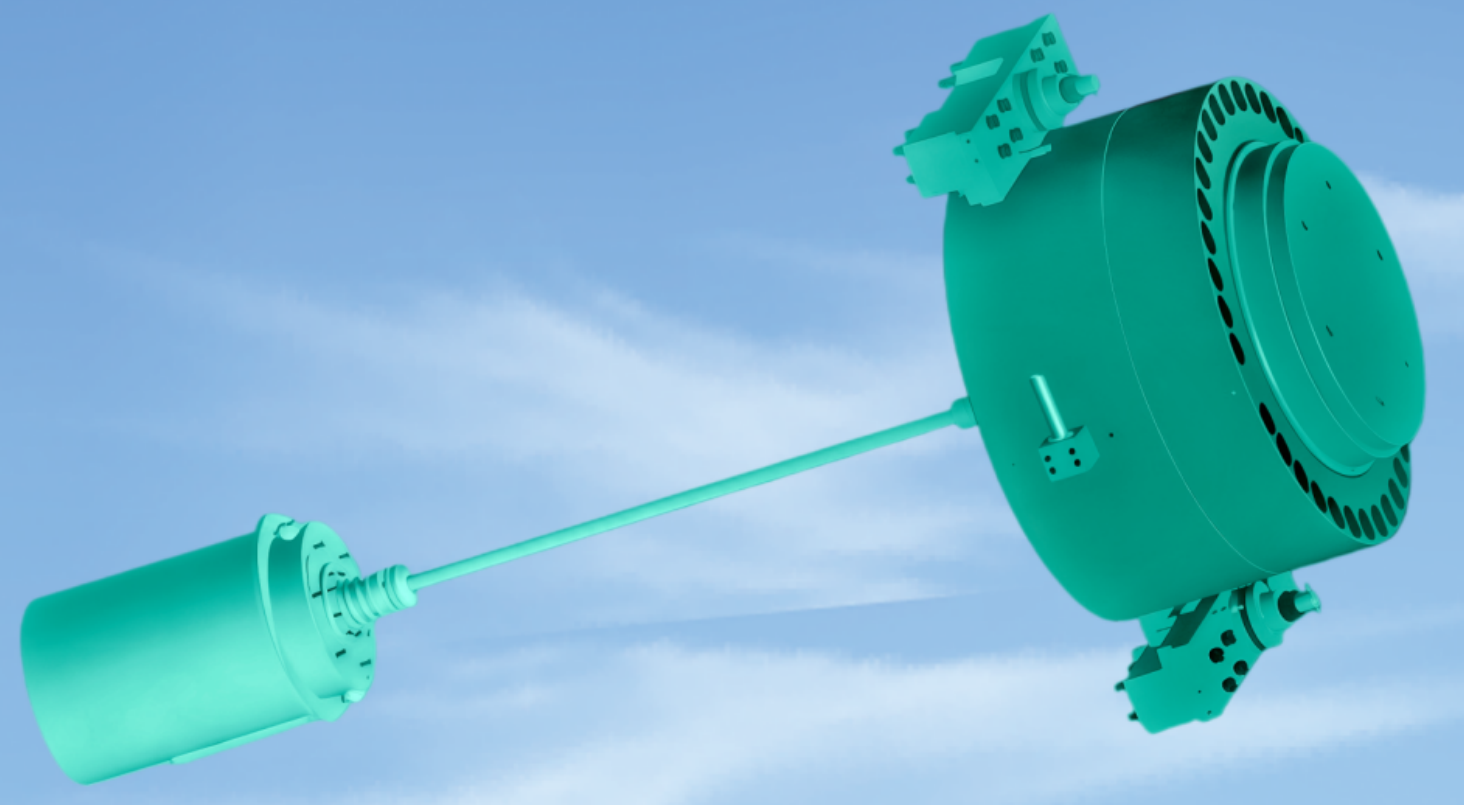

Flexible Configurations

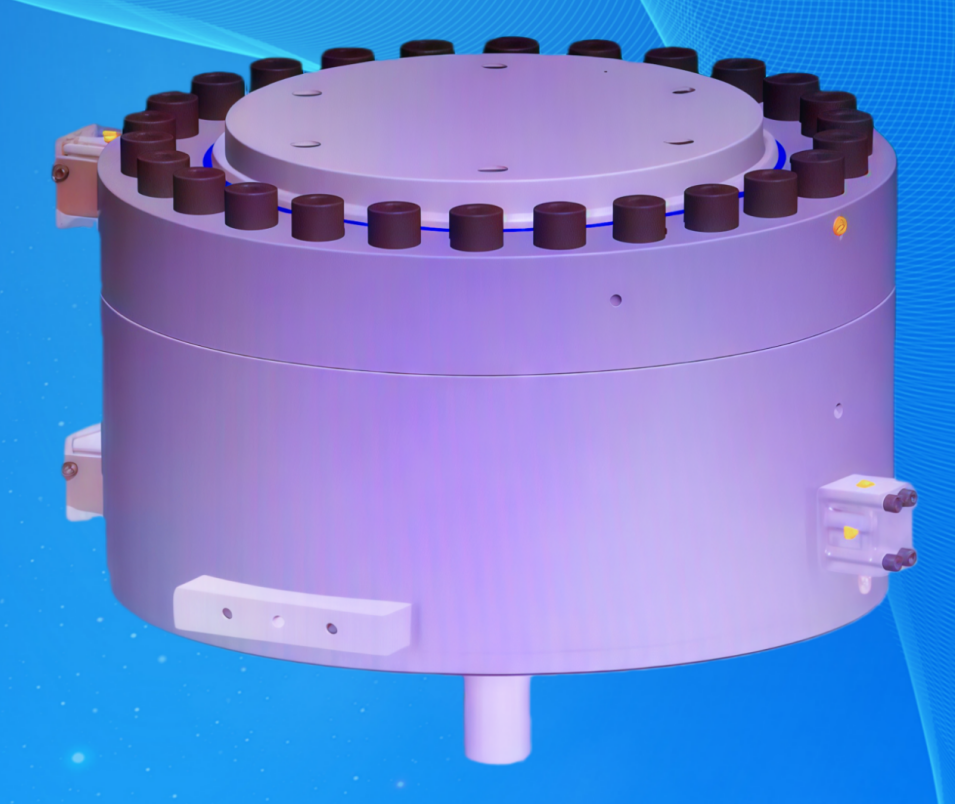

Sensors

• Pressure / force sensors

• Internal or external magnetostrictive sensors

• Magnetic scale / optical scale

• LVDT displacement sensors

Valve Options

• Servo valves (MOOG)

• Manifold / cartridge valves

• Pressure test & air-bleeding ports

Structural Options

• Spherical bearing

• Metal protective cover / bellows

3. Manufacturing & Quality Assurance

All cylinders comply with:

• GB/T 32216-2015 (Proportional/servo cylinder test method)

• DIN ISO 10100:2022 (Hydraulic cylinder acceptance test)

100% inspection of all components with records archived for 10+ years.

Core Manufacturing Process

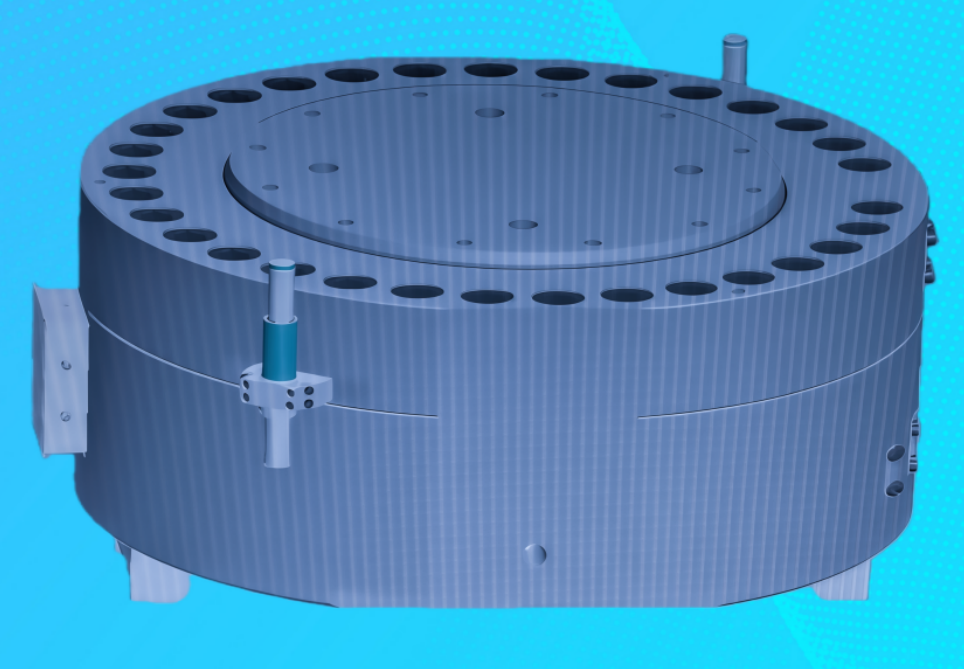

Cylinder Barrel

• 42CrMo forging, UT tested

• Precision boring & honing

• Hard chrome plating ≥0.08mm, HV ≥800

• Surface roughness ≤ Ra0.4 μm

Piston Rod

• 42CrMo quenched & tempered

• Hard chrome plating ≥0.08mm

• Roughness ≤ Ra0.2 μm

Seals

• High-pressure, low-friction servo seals (PTFE + NBR)

• Clean-room assembly

4. Full Testing (Curves Provided)

Static Tests

1.5× rated pressure, 10-min holding

• Zero permanent deformation & Zero leakage

• Internal leakage ≤1MPa drop in 5 min

• Starting pressure ≤0.01MPa

• Friction variation ≤±5%

Dynamic Tests

• Step response ≤25–50ms

• Overshoot ≤10–15%

• Frequency bandwidth ≥10Hz

• Position accuracy ≤±0.005mm

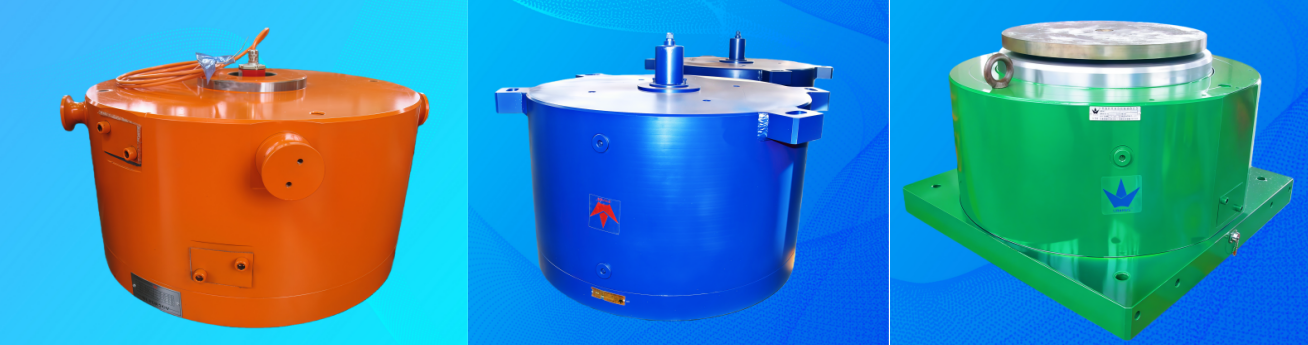

Testing Bench (Largest in China)

• 8000-ton push-pull load

• 35MPa, 1000L/min hydraulic power

• MOOG 792 servo valve

• ±0.01mm displacement accuracy

5. Reliability

Failure-free service life:

1–5 years (≥1,000,000 cycles)

AGC series servo hydraulic cylinder technical parameter table

| Cylinder diameter | Rod diameter | Working force at different operating pressures (KN) | Cylinder diameter | Rod diameter | Working force at different operating pressures (KN) | ||||||||

| 10MPa | 16 MPa | 21 MPa | 25MPa | 28MPa | 10MPa | 16 MPa | 21 MPa | 25MPa | 28MPa | ||||

| 300 | 260 | 707 | 1131 | 1484 | 1767 | 1979 | 800 | 750 | 5027 | 8042 | 10556 | 12566 | 14074 |

| 350 | 300 | 962 | 1539 | 2020 | 2405 | 2694 | 860 | 800 | 5809 | 9294 | 12199 | 14522 | 16265 |

| 360 | 320 | 1018 | 1629 | 2138 | 2545 | 2850 | 900 | 840 | 6362 | 10179 | 13360 | 15904 | 17813 |

| 380 | 340 | 1134 | 1815 | 2382 | 2835 | 3176 | 1000 | 900 | 7854 | 12566 | 16493 | 19635 | 21991 |

| 400 | 1257 | 2011 | 2639 | 3142 | 3519 | 1050 | 8659 | 13854 | 18184 | 21648 | 24245 | ||

| 420 | 360 | 1385 | 2217 | 2909 | 3464 | 3879 | 1100 | 1000 | 9503 | 15205 | 19957 | 23758 | 26609 |

| 450 | 400 | 1590 | 2545 | 3340 | 3976 | 4453 | 1200 | 1100 | 11310 | 18096 | 23750 | 28274 | 31667 |

| 480 | 420 | 1810 | 2895 | 3800 | 4524 | 5067 | 1300 | 1200 | 13273 | 21237 | 27874 | 33183 | 37165 |

| 500 | 450 | 1964 | 3142 | 4123 | 4909 | 5498 | 1400 | 1300 | 15394 | 24630 | 32327 | 38485 | 43103 |

| 550 | 500 | 2376 | 3801 | 4989 | 5940 | 6652 | 1450 | 1350 | 16513 | 26421 | 34677 | 41283 | 46236 |

| 600 | 550 | 2827 | 4524 | 5937 | 7069 | 7917 | 1500 | 1400 | 17671 | 28274 | 37110 | 44179 | 49480 |

| 620 | 580 | 3019 | 4831 | 6340 | 7548 | 8453 | 1600 | 1500 | 20106 | 32170 | 42223 | 50265 | 56297 |

| 650 | 3318 | 5309 | 6968 | 8296 | 9291 | 1700 | 1600 | 22698 | 36317 | 47666 | 56745 | 63554 | |

| 700 | 640 | 3848 | 6158 | 8082 | 9621 | 10776 | 1800 | 1700 | 25447 | 40715 | 53439 | 63617 | 71251 |

| 720 | 660 | 4072 | 6514 | 8550 | 10179 | 11400 | 1900 | 1800 | 28353 | 45365 | 59541 | 70882 | 79388 |

| 760 | 700 | 4536 | 7258 | 9527 | 11341 | 12702 | 2000 | 1900 | 31416 | 50265 | 65973 | 78540 | 87965 |

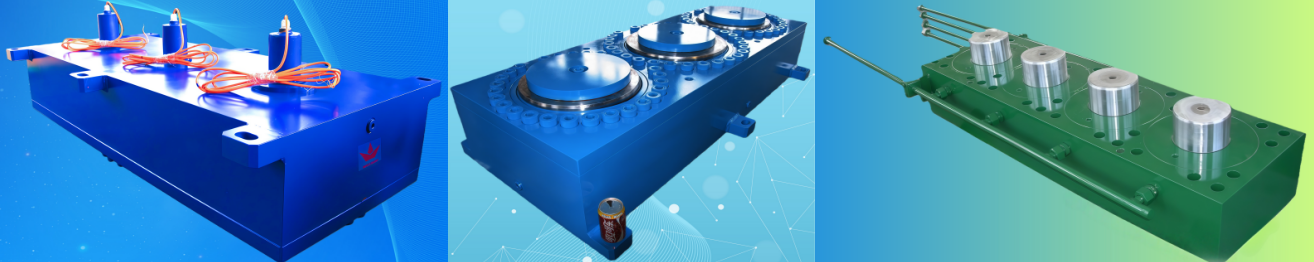

6.Typical Project Cases

1. Name: AGC Servo Hydraulic Cylinder; Model:UAGCT940/860-148 SONY

Bore r: 940, Rod : 860, Stroke: 148; ; External SONY Magnetic Scale

Working Pressure: 28MPa, Test Pressure: 35MPa

2.Name: AGC Servo Hydraulic Cylinder; Model: UAGC800/740-210

· Bore : 800, Rod : 740, Stroke: 210; Working Pressure: 25MPa, Test Pressure: 37.5MPa

3.Name: AGC Servo Hydraulic Cylinder; Model: UAGC1600/1450-85H

· Bore : 1600, Rod : 1450, Stroke: 85

· Working Pressure of Rodless Chamber: 27MPa, Test Pressure: 37.5MPa

· Working Pressure of Rod Chamber: 7MPa, Test Pressure: 10MPa

· Working Medium: N46 · External Displacement Sensor

4.Name: 1450 Eighteen-Roll AGC Servo Hydraulic Cylinder; Model: UAGC760/680-180H

· Bore : 760, Rod : 680, Stroke: 180; Working Pressure: 21MPa, Test Pressure: 31MPa

· Working Medium: N46 · Internal Displacement Sensor

5.Name: Polisher AGC Servo Hydraulic Cylinder; Model: UAGC560/480-385

· Bore : 560, Rod : 480, Stroke: 385; Working Pressure: 23MPa, Test Pressure: 34.5MPa

· Working Medium: Hydraulic Oil

6.Name: 1580 Finishing Mill F4-F7 AGC Servo Hydraulic Cylinder; Model: UST1050/900-170CL(DS)

· Bore : 1050, Rod : 900, Stroke: 170;

· Starting Pressure ≤0.05MPa, Internal Leakage ≤15ml/min, No External Leakage

· Working Pressure of Rodless Chamber: 30.9MPa, Test Pressure: 35MPa

· Working Pressure of Rod Chamber: 6.86MPa, Test Pressure: 10MPa

· Bandwidth ≥15Hz; Internal SONY Magnetic Scale

| Name | AGC hydraulic cylinder 23010105008 | Buyer model | 940/860-148 | Factory No. | 158207 | ||||

| Supplier model | Supplier model | UAGC2306T940/860-148SONY | |||||||

| Cylinder diameter | 940 mm | Rod diameter | 860 mm | Stroke | 148 mm | Rated pressure | 28 Mpa | Oil temperature | 50±5°C |

| Test oil | N46# anti-wear hydraulic oil | Oil cleanliness | Ambient temperature. | 35°C | |||||

| Test item | Test results | ||||||||

| Trail operation | Full stroke reciprocating 10 times. When the speed is ≤ 5mm/s, check for creeping, vibration, etc. | N/A | |||||||

| Full stroke inspection | Measured stroke | 148mm | |||||||

| Buffering effect | N/A | ||||||||

| Minimum starting pressure | Rodless chamber | 0.016Mpa | Rod chamber | 0.01MPa | |||||

| Internal leakage | Rodless chamber | Pressure | 28Mpa | Time | 10min | Pass | |||

| Rodless chamber | Pressure | 28Mpa | Time | 10min | Pass | ||||

| Voltage withstand test | Rodless chamber | Pressure | 35Mpa | Time | 5min | Pass | |||

| Rodless chamber | Pressure | 35Mpa | Time | 5min | Pass | ||||

| External leakage inspection | Test process | Piston rod | Other parts | ||||||

| N/A | N/A | ||||||||

| Dynamic and static friction test |  |

||||||||

|

Dynamic performance test Closed loop logarithm Frequency characteristics |

|

||||||||

| Static pressure holding test |  |

||||||||

| Remarks | |||||||||

| Instructions |

1. This report is a record of the test site and must not be retroactively recorded. 2. The differential cylinder only detects the minimum starting pressure of the rodless chamber; the double-rod cylinder detects the minimum starting pressure of the rod chamber on one side. 3. This report is invalid without the signature and official seal of the company's full-time inspection personnel. |

||||||||

| Tested by: | Reviewed by: | Test date: August 2024 | |||||||

| (Official seal) | |||||||||